Chapter 4 -

Building a USB Adapter

Cable building is a compulsory part of hardware hacking. Many modifications and experiments performed on pieces of hardware wil require a custom cable to adapt your existing connectors to what you need.

In this chapter, you will learn how to build a USB adapter cable for the Xbox, something not available in most retail outlets (although select online vendors, such as Lik-Sang (www.lik-sang.com) do carry this item). A USB adapter allows standard USB hubs, keyboards, and mice to be connected to the Xbox for the purpose of running Linux. (This chapter presents the basics of robust cable building in a tutorial fashion; experienced hardware hackers should feel free to skim or skip it.)

Starting Materials

This project requires the following materials:

• One Xbox game controller breakaway cable replacement or game controller extension cable. (See Figure 4-1.)

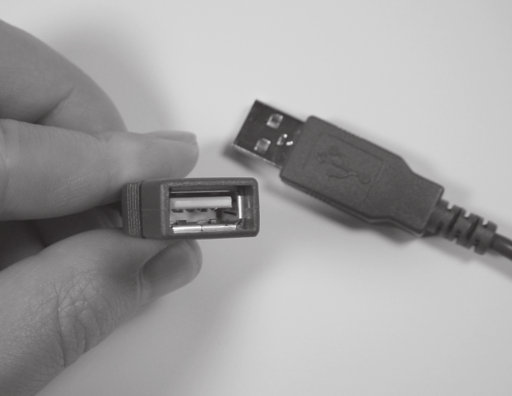

• One USB type A extension cord or a USB type A female socket. (A picture of a USB type A female socket is shown in Figure 4-2.)

• A soldering iron, solder, and flux.

• A diagonal wire cutter and a wire stripper.

• Electrical tape.

• (Optional) 3/8" heat shrink tubing and hot-glue.

• (Optional) Third hand soldering aid.

The step-by-step description in this chapter uses a breakaway replacement cable (available at any video game retailer), and the USB extension cord. If you want to use something different, see Appendix F, “Xbox Hardware Reference,” for the pinouts of the various connectors employed by the Xbox.

Figure 4-1: (Left) an Xbox game controller extension cable. (Right) an Xbox breakaway cable.

Figure 4-2: USB type A female connector.

Strategy

When building the Xbox USB adapter cable, the basic idea is to cut the Xbox breakaway cable and the USB extension cable in half and to join the proper ends of the two cables. Fortunately, there is a standard wiring code for USB-compliant cables. Red is +5V power, black is Ground, White is Data (-), and Green is Data (+). In order to join the cables together, simply connect wires of like colors together. (Note that the Xbox cable will have an extra yellow wire that carries a copy of the composite video sync signal for use in light-gun type game interfaces. This extra yellow wire can be safely ignored.) This chapter will walk you step-by-step through connecting the wires and sealing the cable.

Warning

Some USB cable manufacturers do not comply with the standard USB wiring code. The most common deviation is reversing the white and green wires, although on rare occa-sion the color code is ignored outright. It is always a good idea to use a continuity meter to verify that your USB extension cable actually complies with the USB color code.

Implementation

First, cut the Xbox breakaway cable near (about 2") the Xbox connector end, and cut the USB extension cable near the female connector end. Discard the male half of the USB extension cable and the half of the Xbox cable with the smaller connector.

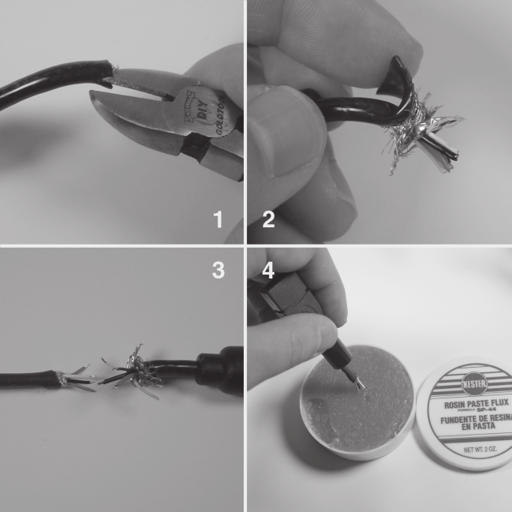

Next, use the diagonal cutters to cut 1/2" slits into the insulation of each cable, as illustrated in frame 1 of Figure 4-3. Peel the insulation back to reveal the wires, which will be protected by a braided metal shield and some metal foil. Peel the metal braiding and foil back, and cut off the excess insulation and shielding. Strip the ends of the red, green, white, and black wires so that about 1/8" of bare conductor is showing. (Do not strip the yellow wire in the Xbox breakaway cable.) Dip the bare ends of the conductors into some solder flux. (See Figure 4-3.)

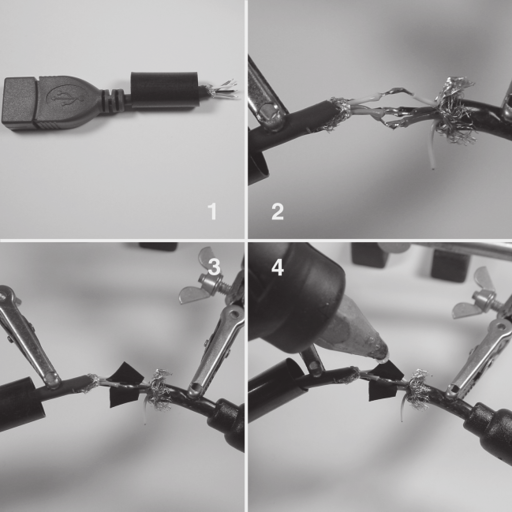

If you are concerned about the robustness or safety of the adapter cable assembly, slip a 1-1/4" segment of heat shrink tubing onto one of the cables. (This tubing will later be slipped over the bare solder joints and filled with hot glue to make a robust connection.) The shielding is not mandatory, but the cable will not be as robust without the heat shrink reinforcement; it will be susceptible to breakage if subjected to repeated bending or straining.

Continue the cable building process by soldering together wires of like colors, as shown in Figure 4-4. Have a friend help you hold the cables in place while you solder them, or use a “third hand” tool (Jameco order number 26690) with alligator clips to hold the cable in place. All of the solder joints should look smooth and shiny. Give a firm tug on each joint to verify that the solder connection is good. Wrap a small piece of electrical tape around the open joints to prevent the exposed joints from shorting together. Test the cable before proceeding to the next step where the joints will be permanently encased.

Figure 4-3: (1) Cut slits in the cable insulation and (2) peel the insulation back to reveal the wires and shielding inside. (3) Cut off the excess shielding and insulation, and strip 1/8” off the end of the wires. (Note how the yel ow wire in the Xbox connector cable at right is not stripped.) (4) Finally, dip the stripped wire ends in soldering flux.

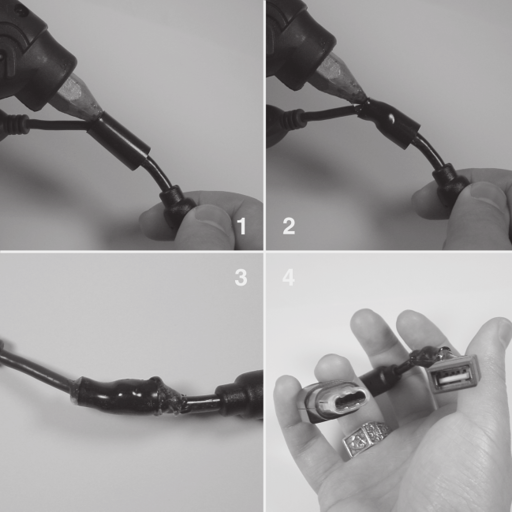

Once the cable has been tested and confirmed to be good, it is time to put a robust casing around the solder joints for mechanical reinforcement, as shown in Figure 4-5. Place a couple of small dabs of hot glue over the open solder joints to hold them in place so they do not short against each other, slip the heat shrink tubing over the solder joints, then fill both sides of the tubing with hot glue. The tubing should shrink from the heat of the glue and form a solid, permanent conformal case over the joint. (The hot glue acts as a strain relief for the joint as well, thus the cable will be robust under most normal operating circumstances.)

Figure 4-4: (1) Slip a piece of heat shrink tubing over the cable before soldering. (2) Solder the wires together, like color to like color. (3) Wrap the wires in electrical tape to prevent shorting. Test the cable. (4) Apply small dabs of hot glue to the tested cable to hold the electrical tape and wires in place for the next step.

Although the cable is fully operational without the hot glue and heat shrink tubing treatment, you can still improve the connection’s stability if you do not have these items handy. Electrical tape can be wrapped carefully around the individual joints as a makeshift mechanical reinforcement.

Now that you have finished your USB to Xbox game port adapter, Chapters 11 and 12 describe some of the steps necessary to install Linux on the Xbox so you can use your new adapter.

Figure 4-5: (1) Slide the heat shrink tubing over the joint, and begin filling the tube with hot glue. (2) The hot glue will cause the heat shrink tubing to collapse. (3) The end product is a permanent conformal casing that will stand up against most abuse. (4) A picture of the final product, showing the Xbox and USB cable ends.