Fully Productive Time is time recorded in the work order which was actually spent working on the operation at the work center. Odoo records the different types of times in the work order depending on the worker's activity. Other than Fully Productive Time, there are other times recorded such as Material Availability, Equipment Failure, Setup and Adjustments, which block operations, and affect the efficiency of the work center. The blocking time is also recorded in the work center, and it affects the OEE.

Let's jump into the configuration related to the time in the work center and routing to process the operation or job at the work center.

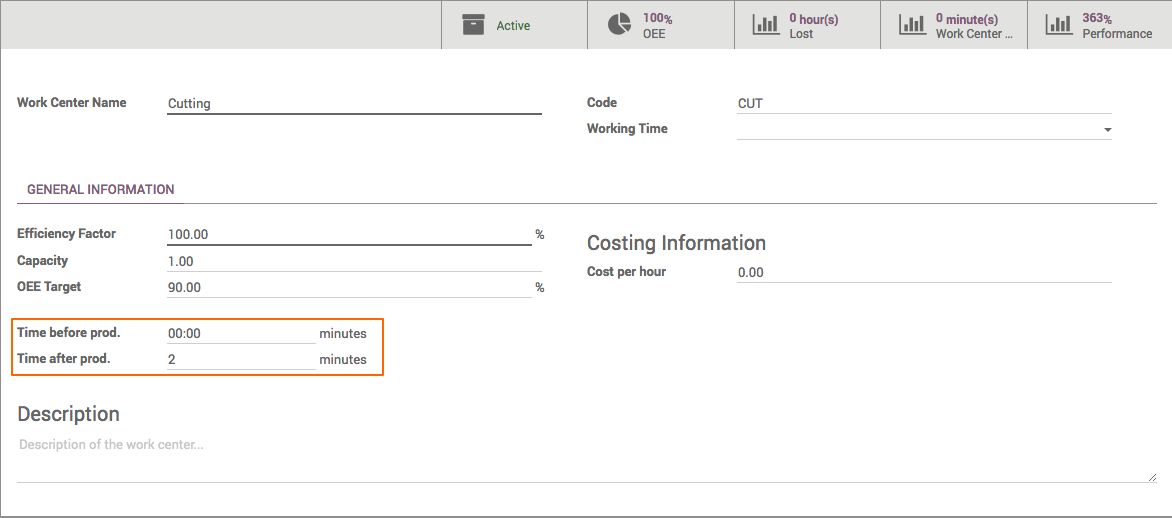

The time required to ready the work center before starting the job, or the time spent after completing the job to clean the work center, has to be configured on the work centers. The following screenshot shows the configuration of the Cutting work center:

Efficiency Factor indicates the efficiency of a machine. In the case of machines, it can be 100% when it is new, or it has to be measured from time to time and the correct efficiency is set to get the accurate performance of the work center.

Capacity represents the capability of the work centers to execute a number of parallel operations. Set it to five if you have five work centers that perform the same operation in parallel.

OEE is computed by Odoo based on the productive and unproductive times; the OEE achieved at the work center should be more than or equal to the OEE Target.

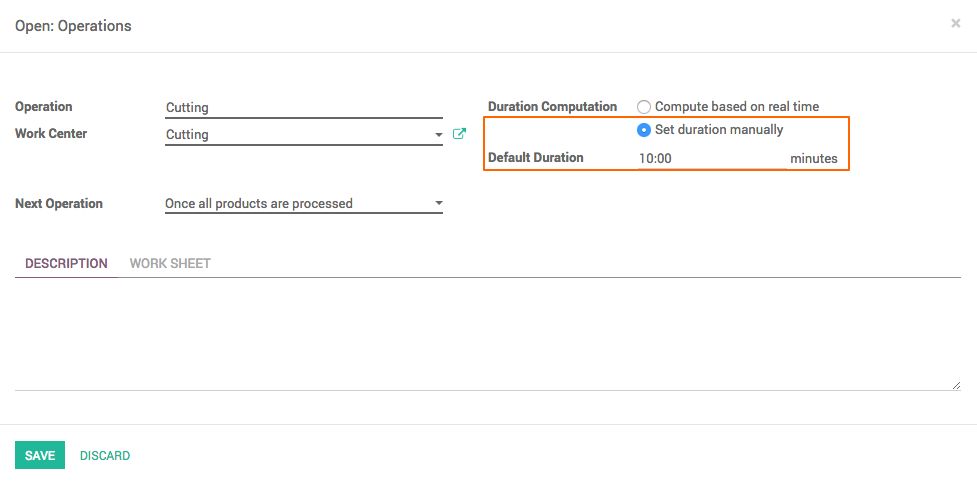

The operating time can be configured in routing; it is the time given at the work center to complete an operation, and can be set as a fixed time or computed dynamically based on some of the past operations performed at the work center.

Some assembly lines set a fixed time for operations. In the next screenshot, the operation time configuration is fixed to 10 minutes to perform the Cutting operation:

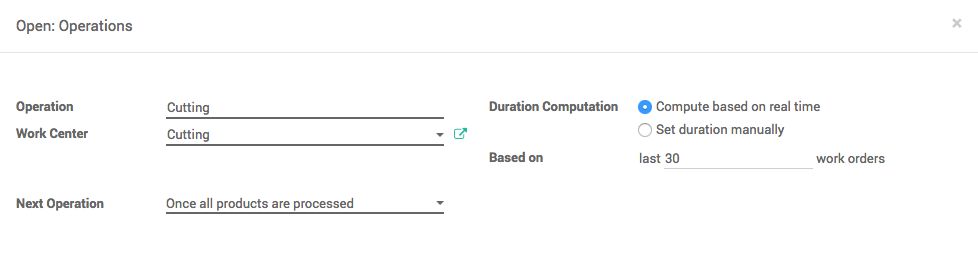

If you would like to set the operation duration based on real-time data available based on the past operations, you can set the Duration Computation field to Compute based on real time. Set the number of past operations in the Based on the field to compute the average time to be given to the next operation performed at the work center. In the following screenshot, the real-time data is computed Based on the last 30 operations:

So, the expected duration will be computed based on the last 30 operations. We may have some workers who are super fast, while some may be slower. The average time will be computed based on their operation duration.

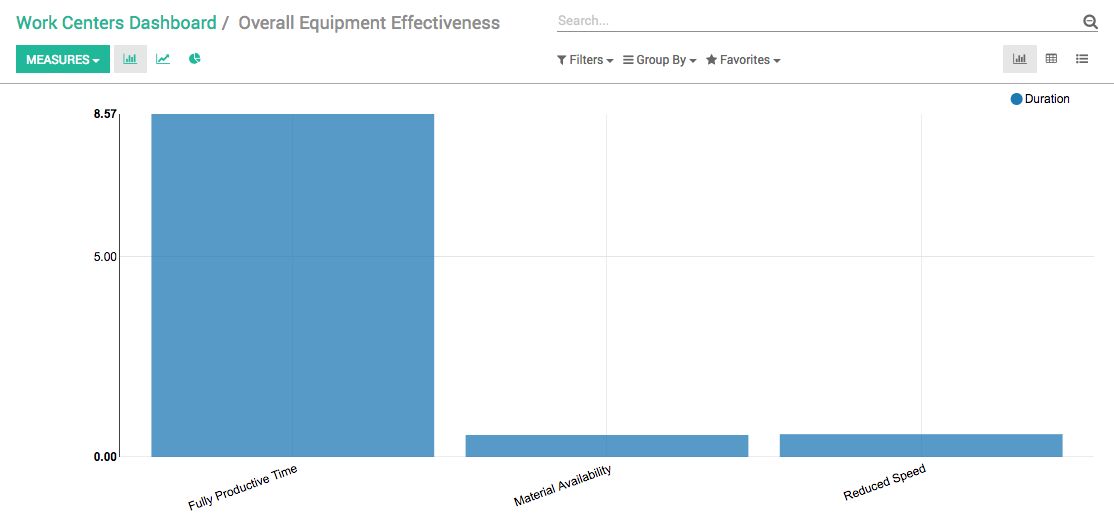

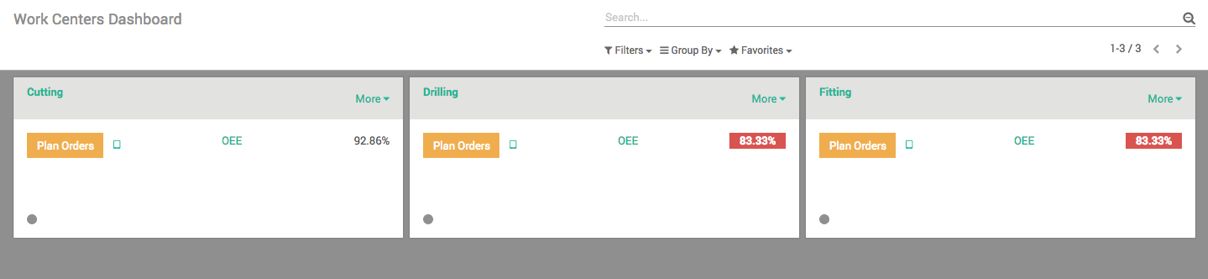

Let's check the status on the dashboard for the OEE of the work centers. I have processed some manufacturing orders to simulate the actual process, as seen in this screenshot:

The Cutting work centers have an OEE of 92.86%, which is normal, as it is above expectation. The expected OEE is 90%. Drilling and Fitting have an OEE of 83.33% and shows an alert as they are below the expected OEE.

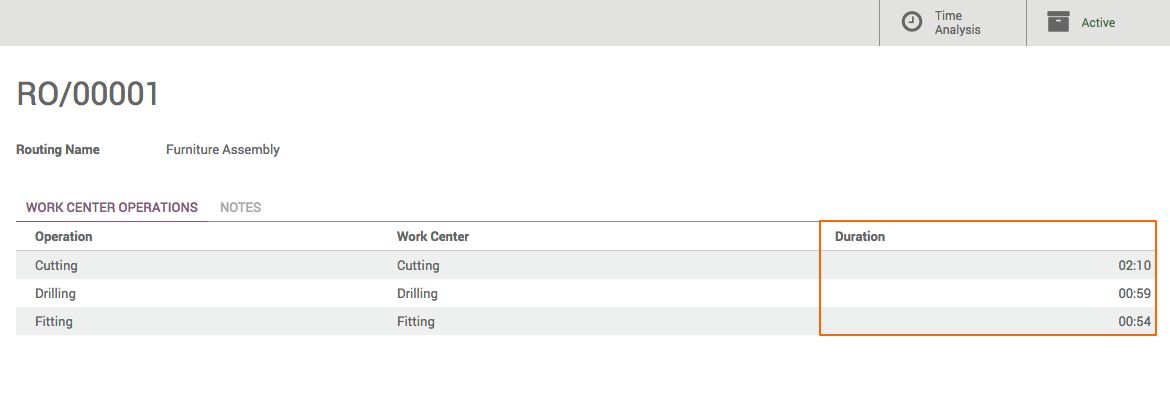

The duration will be computed automatically on the routing based on the last 30 work orders processed at the work centers. Look at the following screenshot of routing:

For the next work order created for Computer Desk, the operation time for the work centers will be taken from the duration computed in the routing. The time computed on the routing does not include the time required to be spent before and after production.

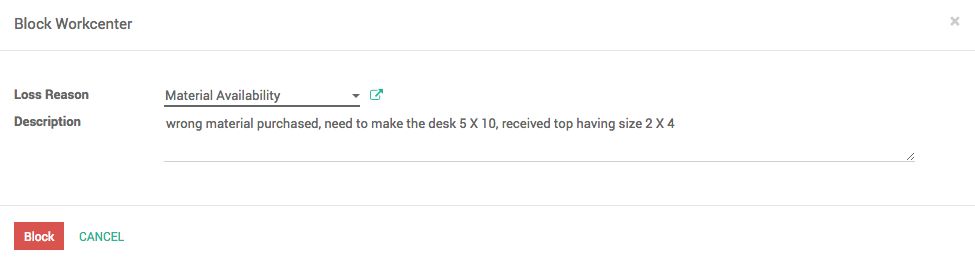

Assuming that the order has been planned but the material has not arrived, or it has arrived but with a different size and shape, we have to wait until the required material arrives. Until then, it has to be marked as time lost due to material unavailability. Click on the gray icon visible on the work center screen; a popup will appear asking you for the Loss Reason and Description of blocking, as seen in this screenshot:

Select the reason, enter the description, and click on the Block button. The work center goes to the block stage, and you cannot process any work orders on that work center. When you check the OEE report, a Material Availably of a one-time loss is recorded at the work center, which affects the overall work center OEE, as seen in this screenshot: