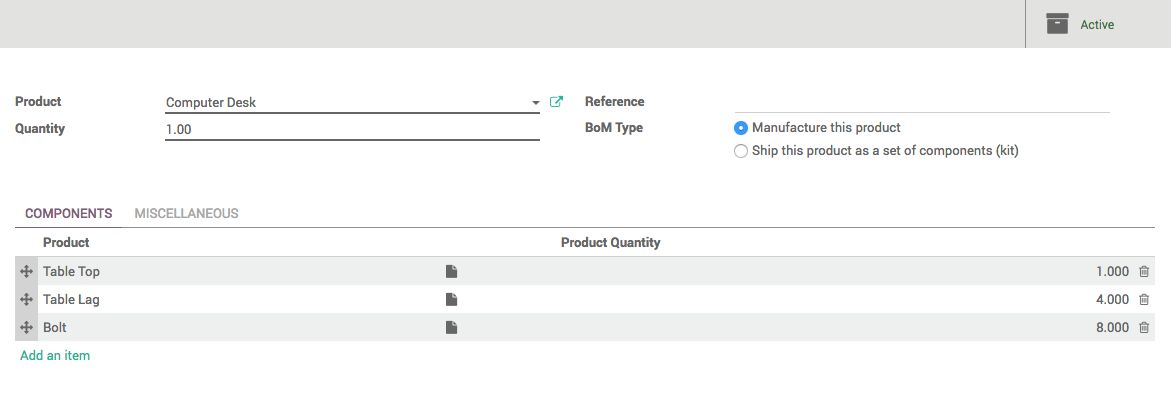

The bill of material defines the list of components to be used to manufacture the finished product; in our case, the finished product is Computer Desk, and the components are Table Top, Table Lag, and Bolt. The bill of material can be accessed from Manufacturing | Master Data | Bill of Materials. Have a look at the bill of material for Computer Desk in the following screenshot:

To produce one quantity of Computer Desk, we need components that are listed on the COMPONENTS tab.

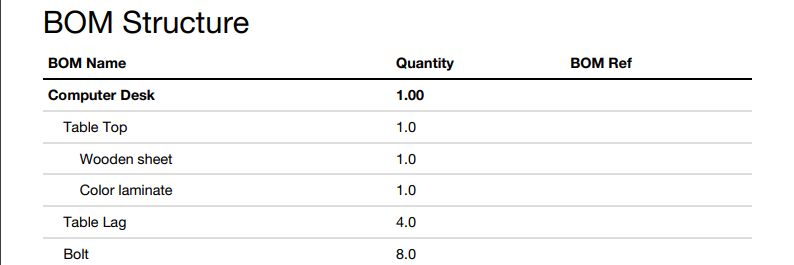

It may be possible that the components are manufacturing products; such components are called semi-finished products. For example, to provide a configurable Table Top, we start manufacturing the Table Top ourself, depending on the requirement, and then the semi-finished component will be used to produce the Computer Desk.

We should first create the bill of material for Table Top by adding the Wooden Sheet and Color Laminate as a component on it, and later, the Table Top can be used as a component in the Computer Desk bill of material:

The bill of material structure can be printed from Print à BOM Structure. The menu is available in the bill of material from view. The preceding screenshot shows the bill of material for Computer Desk.

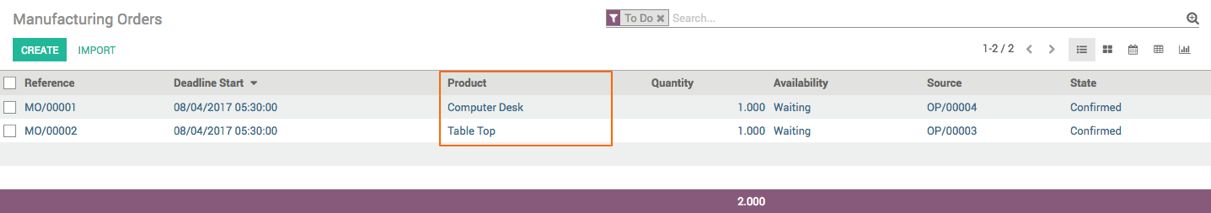

Let's try to sell the Computer Desk. If everything is configured well, you will get two manufacturing orders, one for Computer Desk, and another for Table Top. Look at the screenshot for the list of manufacturing orders. The manufacturing order for Table Top has to be processed first—we cannot produce the Computer Desk without Table Top, as Table Top is one of the raw materials:

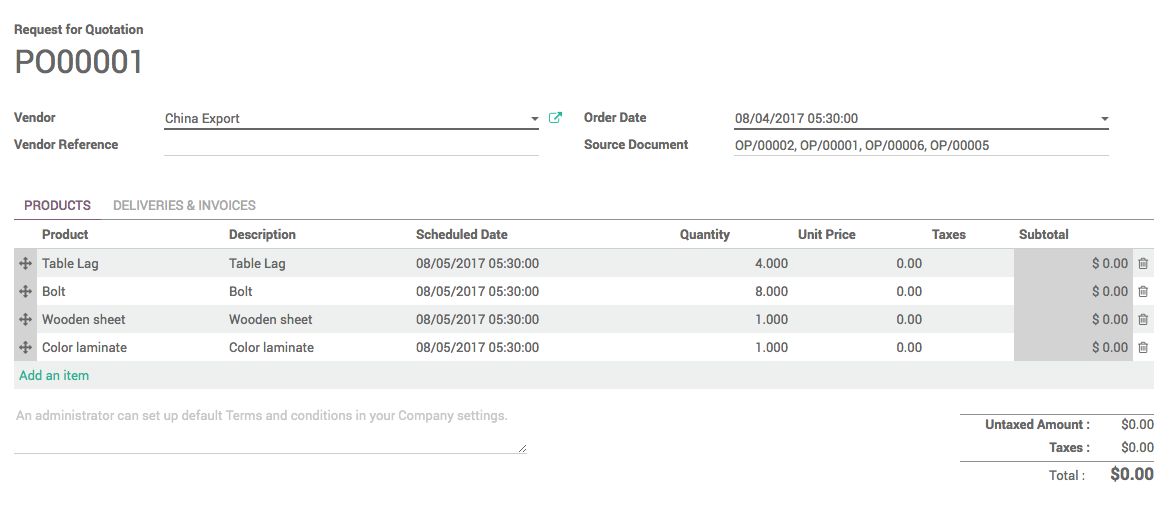

You will also get the request for a quotation for all the raw materials that are required to produce the Table Top and Computer Desk.

Orders may vary depending on the vendor configuration for the product. For me, the whole order goes to a single vendor, as the same vendor is configured on all the components, as you can see in the following purchase order:

The bill of material has an important role in the manufacturing process; the modification in the bill of material requires input from the different departments to verify and confirm the availability of components or a process design.