Unlike the three-step delivery, it is possible to have a three-step reception where all incoming products are first unloaded to the input location, transferred to quality check and finally, transferred to the stock.

Activate the option Unload in input location, go through a quality control before being admitted in stock (3 steps) on the warehouse Incoming Shipments field.

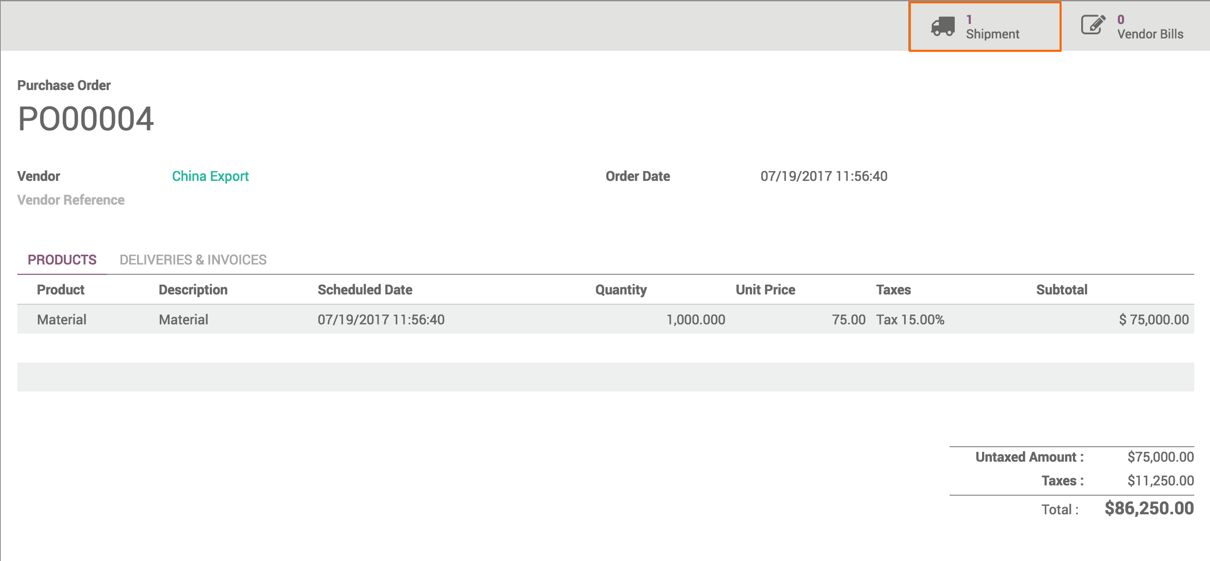

To test the flow, let's create a Purchase Order for the Material product. Look at the following screenshot of the order:

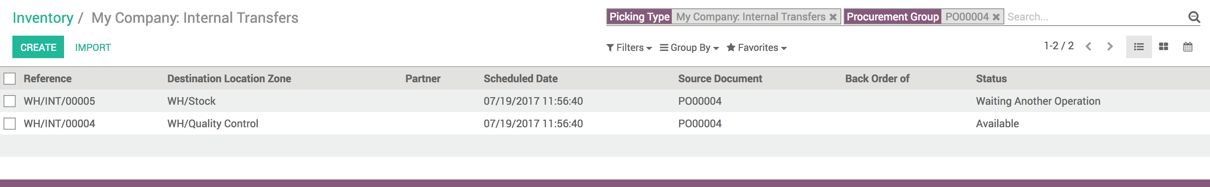

You will be able to see the incoming shipment ready for processing which receives the material from the vendor and unloads the Material from Vendor Location to Input Location. There will be two internal moves created as soon as the Reception Order is validated:

The incoming shipment has to be processed when the material is received from the vendor, after the processing of the incoming shipment, the material will be available at the Input Location.

Process the second internal transfer WH/INT/00004 which will transfer the Material from Input Location to the Quality Control Location. Assume that all the material has passed through the quality check process and is ready to move to the Stock Location:

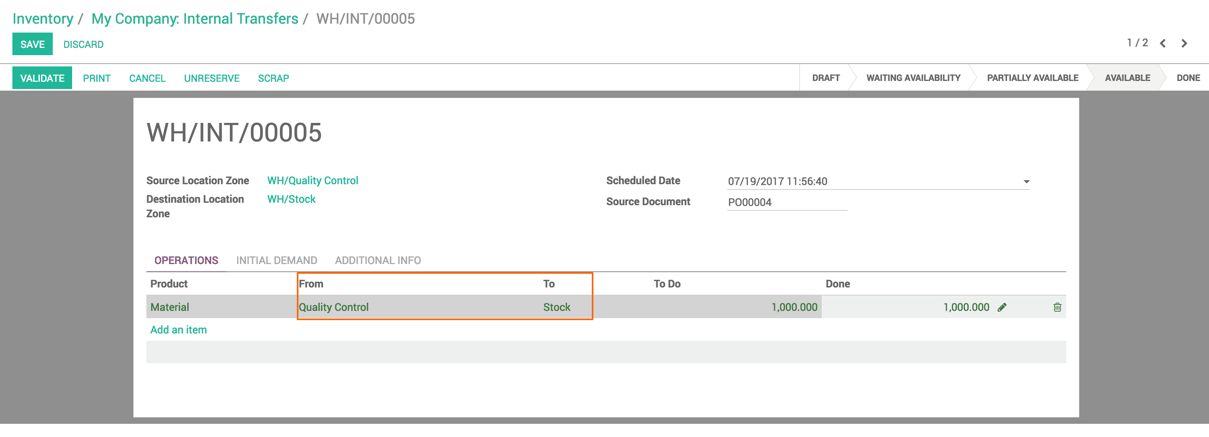

The last internal transfer WH/INT/00005 will be ready to process and finally, it will transfer all 1,000 units to the Stock Location, see the preceding image of the internal transfer.

So, the incoming shipment will be completed as soon as you process the last internal transfer which actually transfers material to the Stock Location. This is called three-step reception. Look at the following operation to see how it works internally in Warehouse:

| Seq | Operation | Source Location | Destination Location |

| 1 | Reception | Vendor | Input |

| 2 | Internal Transfer | Input | Quality Control |

| 3 | Quality Check (INT) | Quality Control | Stock |