Odoo is able to manage multiple warehouses for an organization. It is a standard business case to have more than one warehouse at different locations. The shop gets refilled from the warehouse, where the shop is a small warehouse which asks for re-supply from the big warehouse.

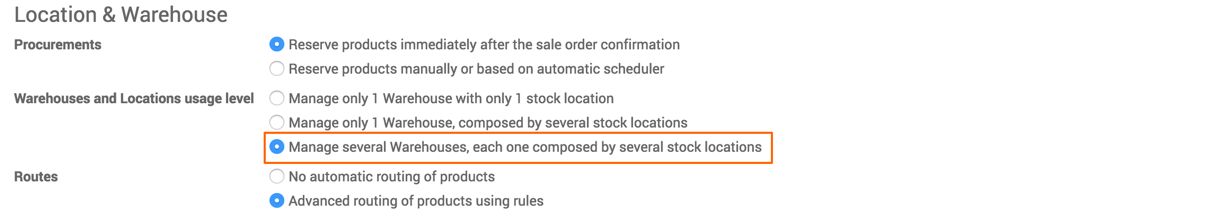

Multiple warehouses can be enabled from the Settings page of the Inventory application. Activate the third option, Manage several Warehouses, each one composed by several stock locations in the Warehouses and Locations usage level field:

Click on the APPLY button and save the settings, the Warehouse menu is available under Inventory | Configuration.

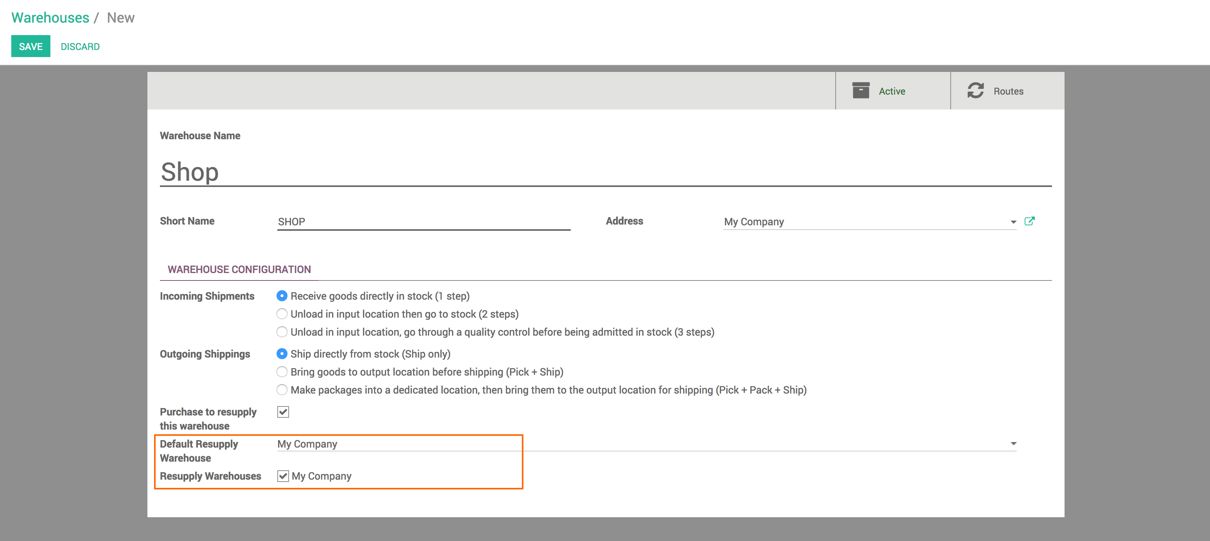

A new warehouse can be created for the same company. Enter the Name, Short Name, Address and select the resupply method, it can be a purchase or resupply from another warehouse. In case you have a multiple resupply warehouse, the default resupply can be selected. Look at the following screen of the warehouse at the shop, if the stock is needed, it will ask My Company warehouse to resupply the required products:

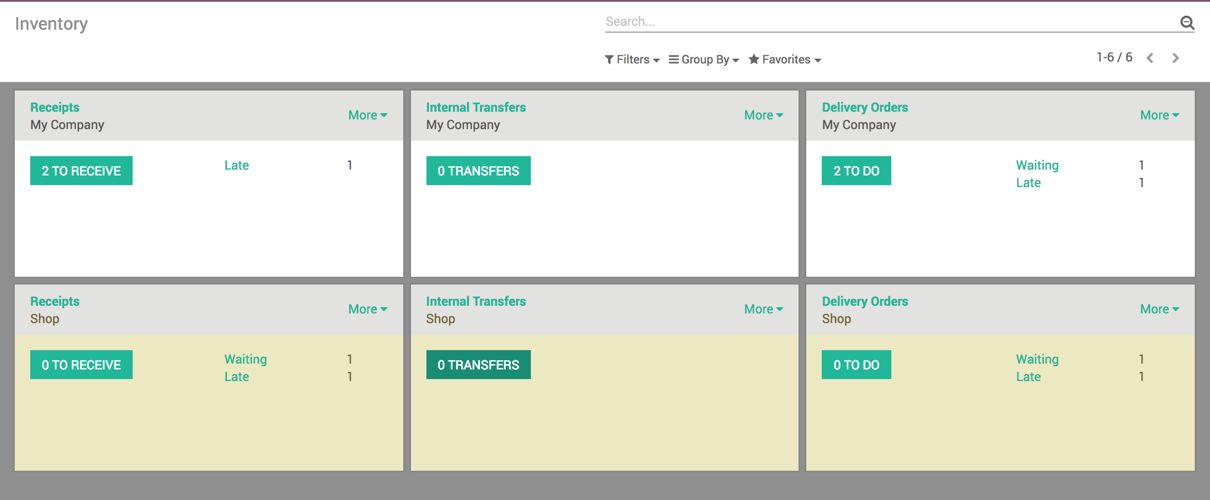

The Inventory dashboard gets a new operation as the warehouse is created. Now you have Receipts, Delivery Orders and an Internal Transfer for the newly created SHOP warehouse:

Let's perform the following steps to test the resupply warehouse feature:

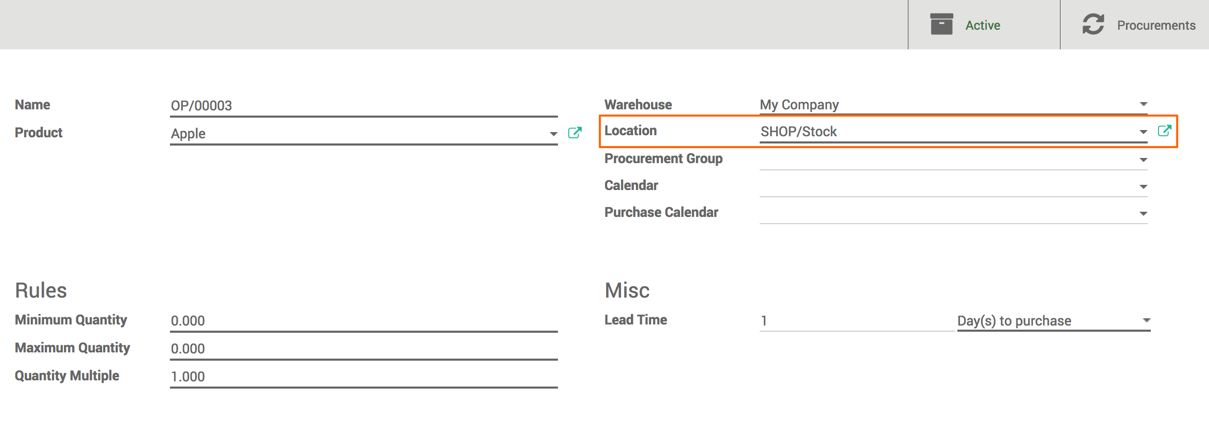

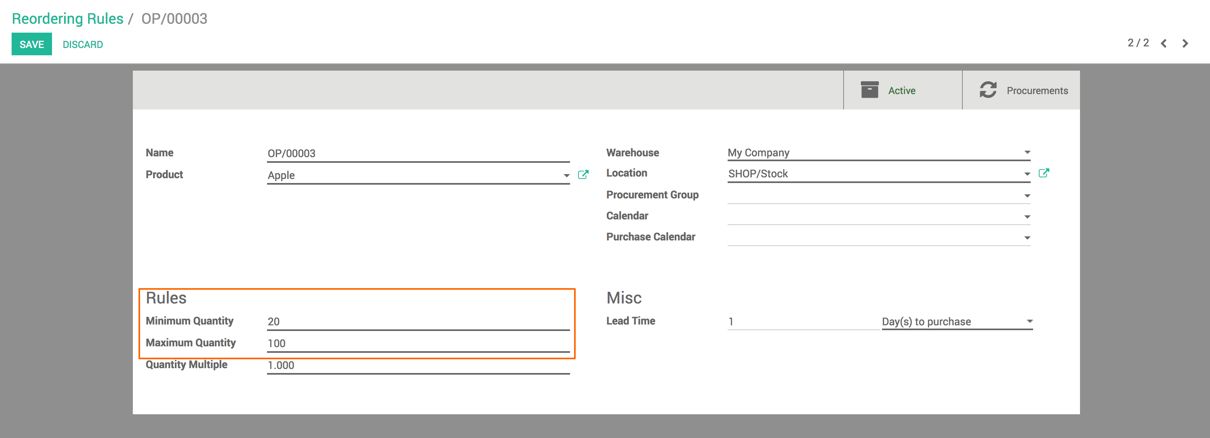

- Create a reorder level for the specific location, in our case SHOP/Stock location. Go to product Apple and create a rule as follows:

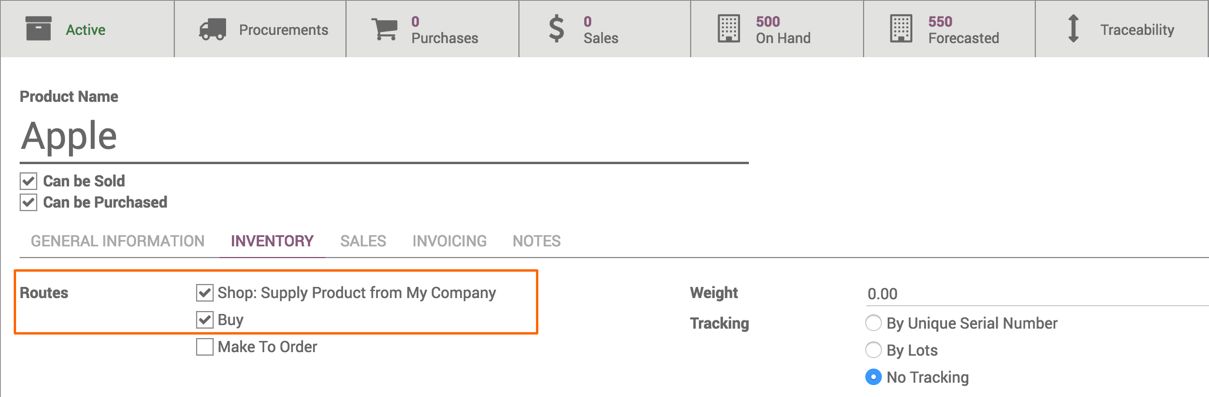

- Select the routes for the product so that procurement can choose the available and possible routes to procure the stock:

- Choose all the possible routes so that depending on the location and based on the reordering policy, the correct routes will be selected during the procurement.

In this case, when the stock of Apple goes down at the SHOP it will be procured from the My Company warehouse and if the stock of Apple goes down at My Company warehouse it will be procured through the standard purchase process, the Purchase Order will be created for the units defined on the reorder level:

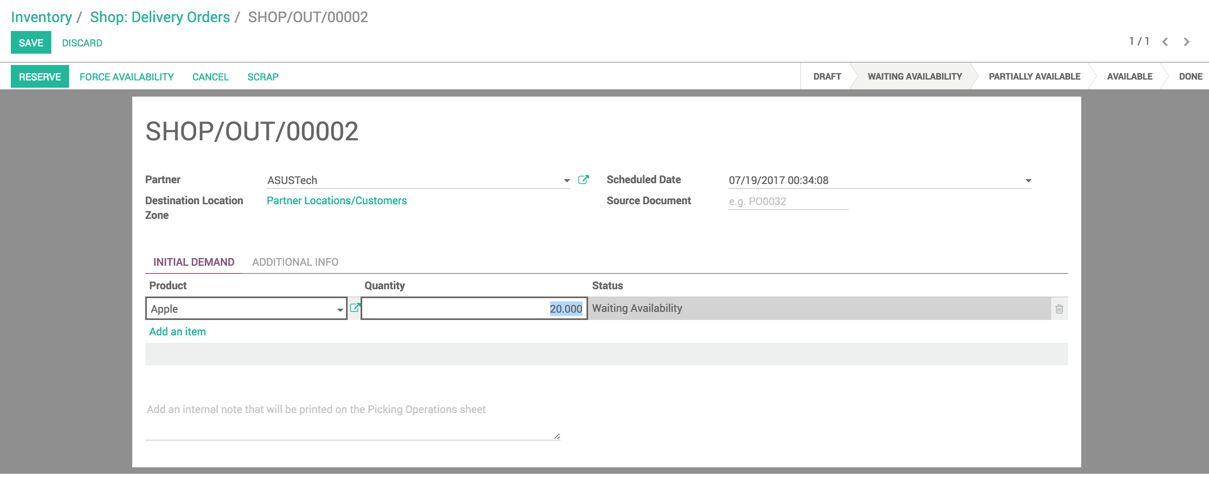

- Let's create the Delivery Order from the SHOP warehouse:

- The procurement is triggered and the following documents will be created as a result:

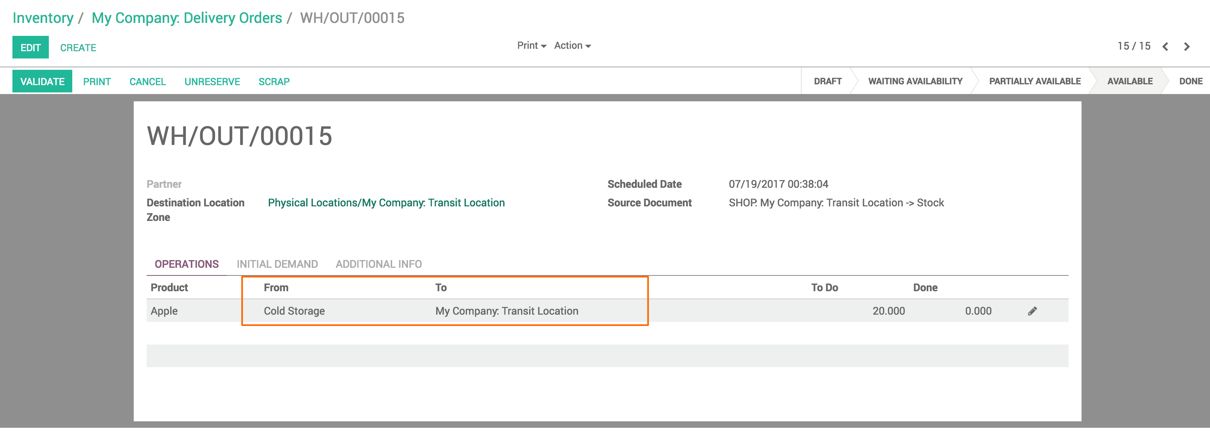

- The Delivery Order in the My Company warehouse, the destination location is My Company: Transit Location

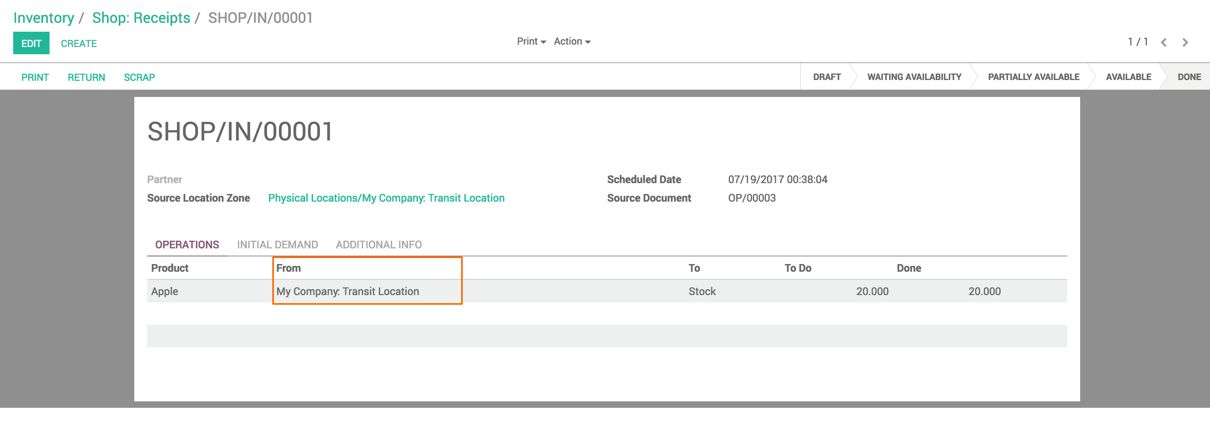

- Incoming Shipment in the SHOP warehouse, where source location is My Company: Transit Location

My Company: Transit Location is a virtual location that work as an intermediate location to transfer products between two different warehouses:

- Look at the Delivery Order in My Company warehouse and assign an Apple from Cold Storage. As soon as the Delivery Order is validated in the My Company warehouse, the incoming shipment in SHOP warehouse will be marked as available. Look at the following screen for incoming shipment in the SHOP warehouse:

- Now the Delivery Order in SHOP will be marked available as the stock is available in the SHOP warehouse. Validate the Delivery Order to deliver from the SHOP warehouse.

- It simulates the real-time business case; the flow is as follows:

- Sales Order created at the SHOP location

- Delivery Order created at the SHOP location based on the Sale Order

- Procurement Order generates the incoming shipment in the SHOP from My Company (My Company: Transit Location)

- Procurement generates the Delivery Order in My Company warehouse. (Deliver to My Company: Transit Location)

- Process delivery from My Company warehouse

- Incoming shipment ready to process at SHOP warehouse, process the incoming shipment in SHOP

- Process the Delivery Order in SHOP, as the stock of Apple is available at SHOP.

At SHOP, it procures the apples according to the demand, if you would like to maintain the minimum stock at SHOP, make sure that you change the reorder rule at the Stock location of SHOP warehouse as follows:

When the stock of Apple goes to 20 or below, make it 100 at SHOP warehouse.