The put away strategy is an advance automation of the internal transfer based on business rules. Let's take an example; you would like to transfer the fruit and vegetables items to the cold storage as soon as they are received in the warehouse.

For all the shipment coming to the stock location, you have to manually transfer the fruit and vegetables to the cold storage. You can automate this based on the put away strategy, so that an automatic transfer is created and it can be transferred to the cold storage:

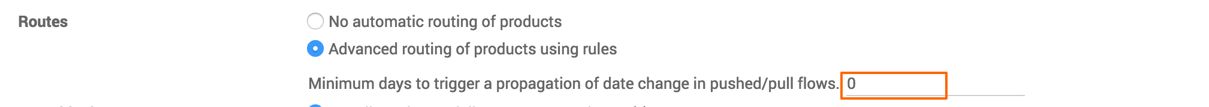

- To activate the put away strategy on a location, the advance routes have to be activated for the inventory. The advance routes can be activated from Configuration | Settings in the Inventory application. Choose Advanced routing of products using rules instead of No automatic routing of products, which is the default option selected on the Routes configuration:

- Enter the number of days after which the internal transfer should be created, this will be applied to all the product categories defined in the put away strategy.

- The removal and put away strategy will be created on the location. Please follow the following rules to create a rule on Stock location to transfer the fruits and vegetables items to the cold storage, when received in stock.

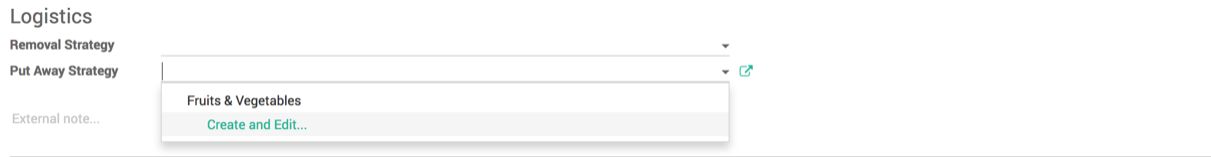

- Go to the locations and search for the WH/Stock location. You will be able to see the Logistics section on form view in the following screenshot:

- Click on the Create and Edit link to create a new strategy on the stock location. This will be triggered as soon as stock gets updated with any incoming shipments:

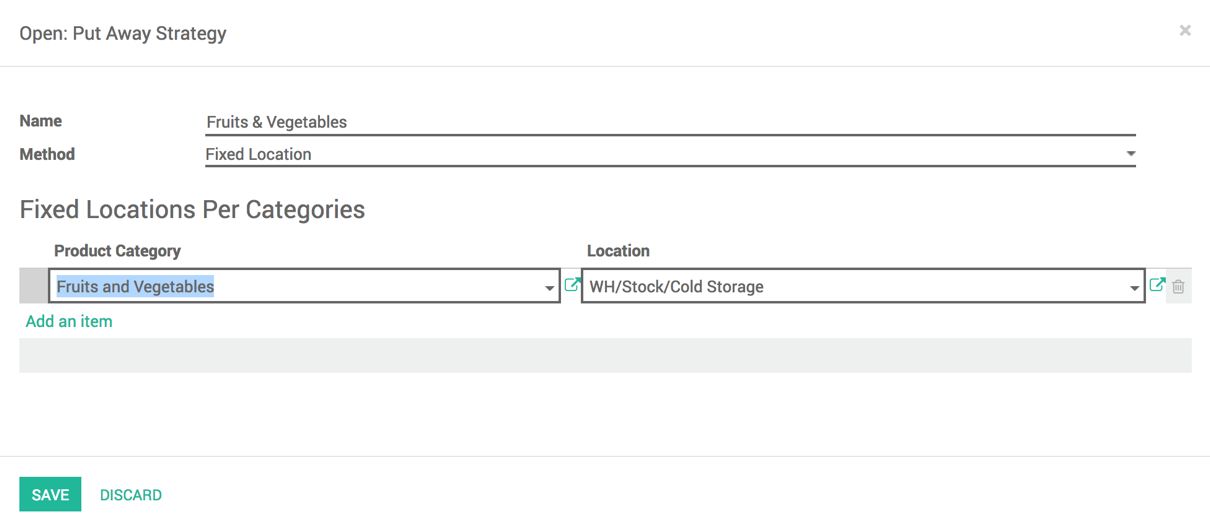

- Enter the appropriate name, select Fixed Location as the method; this is the only method available for the moment. As soon as the method is selected, the category and location mapping list will appear. Enter the product category and select the location to transfer.

- Organize products category in a better way to have an automatic trigger for a selected group of products when any of them arrive in stock.

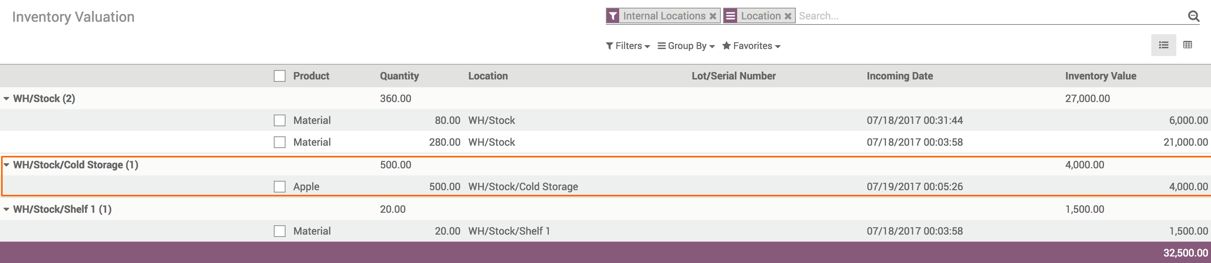

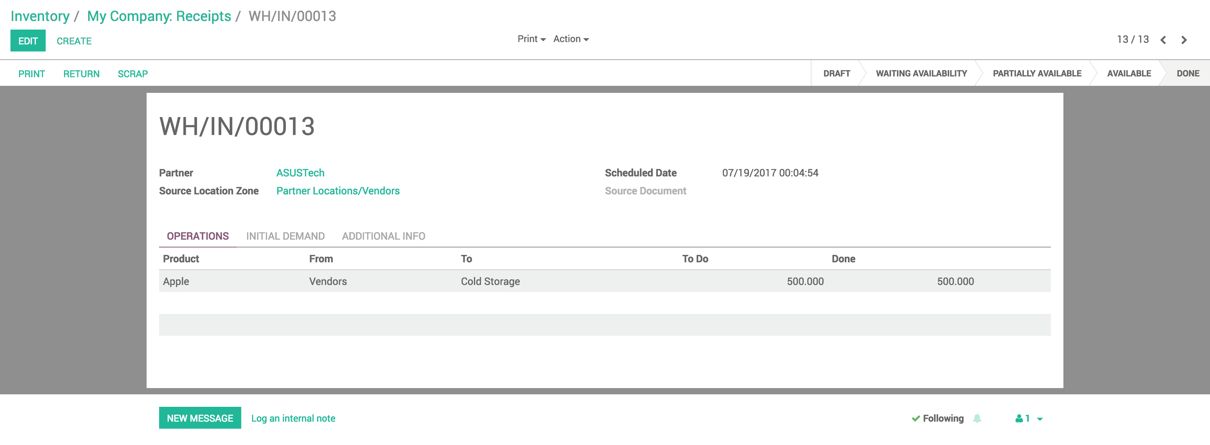

To test the strategy, create and process an incoming shipment in Warehouse with a product belonging to the Fruits and vegetables category. Look at the following screen where I have created an incoming shipment of 500 quantity of apples:

As soon as the incoming shipment is validated, the destination location will be changed to Cold Storage instead of Stock.

All the apples are transferred to the Cold Storage automatically, the same can be tracked from the inventory valuation. Look at the following screenshot: