There are two routes available on the product for the procurement, Buy and Make to Order. The Buy route is called Make to Stock, which means, assign from the stock if available in stock or create a procurement order

According to Make to Order, just create a procurement order as and when the product is required. It means that the stock is not maintained in the warehouse. Either the purchase order or manufacturing order will be created when the procurement runs on both the routes.

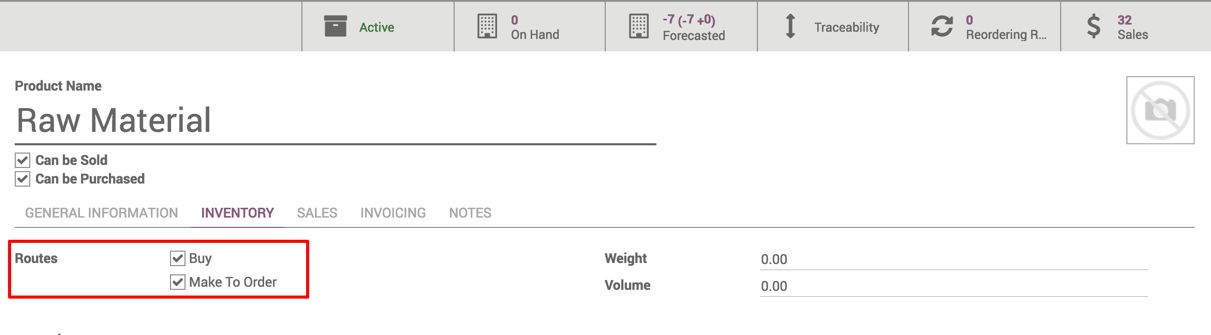

Let's assume that for some product, you have to set it to Make to Order as you do not maintain the stock of material product due to a higher price, fluctuation of the price, or lack of stable demand. In such cases, we buy raw material on demand. In this case, Make to Order has to be selected along with the Buy route on the Raw Material route. Look at the product route configuration in the following screenshot:

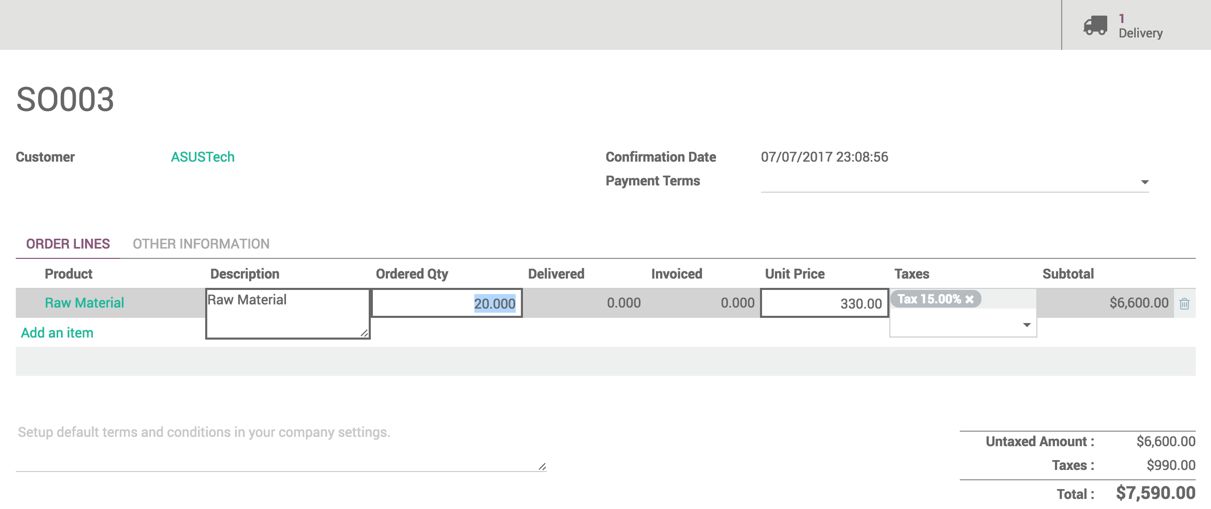

Let's say that you have a customer looking for 20 units. Let's create a sales order for 20 units as soon as the order is confirmed:

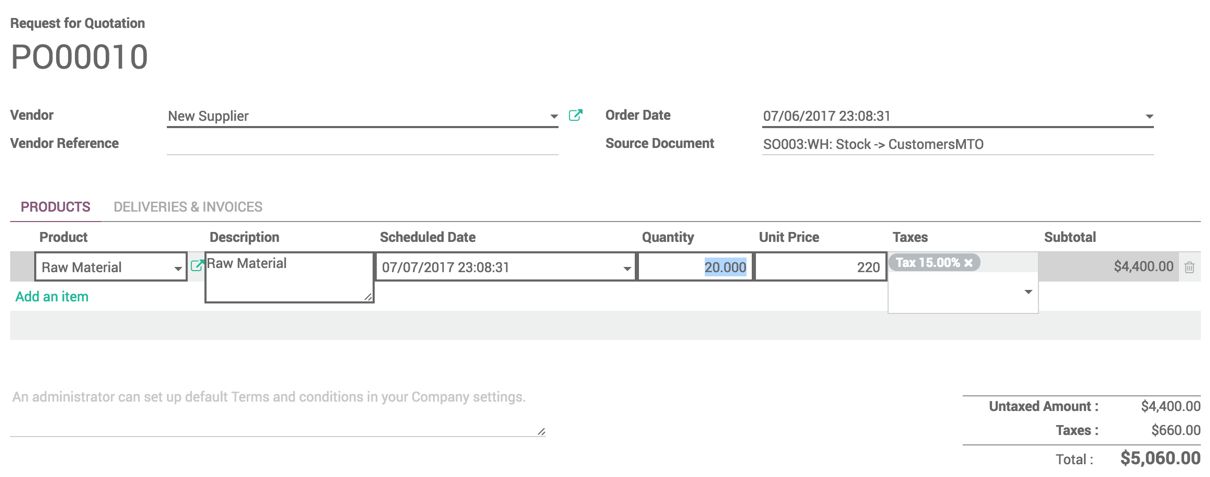

You will get the purchase order for 20 units only, as procurement does not check the stock and does not take care of the reorder rules:

Odoo is not checking for the stock level or reorder level. The procurement order will create a purchase order for the required quantity of the raw material.